Element Tuning Pro Comp CNC Closed Deck Short Block for Subaru, 2.5L Black

Element Tuning's Pro Comp short blocks were born with a racing pedigree. Our engine program has over 13 years of R&D through thousands of miles racing Subaru engines exclusively. Every specification these engines are blueprinted to were derived from our long term racing data. We build the best engines you can buy! We're confident saying this as every aspect of these motors has been tested and verified under the most demanding racing circumstances. Element Tuning Pro Comp Short Block engines are built from 100% new components and starts life from a Subaru STi bare block and a STi forged crankshaft. Blocks are then fitted with billet CNC closed deck inserts, bored to 99.75 mm, honed, and then decked.

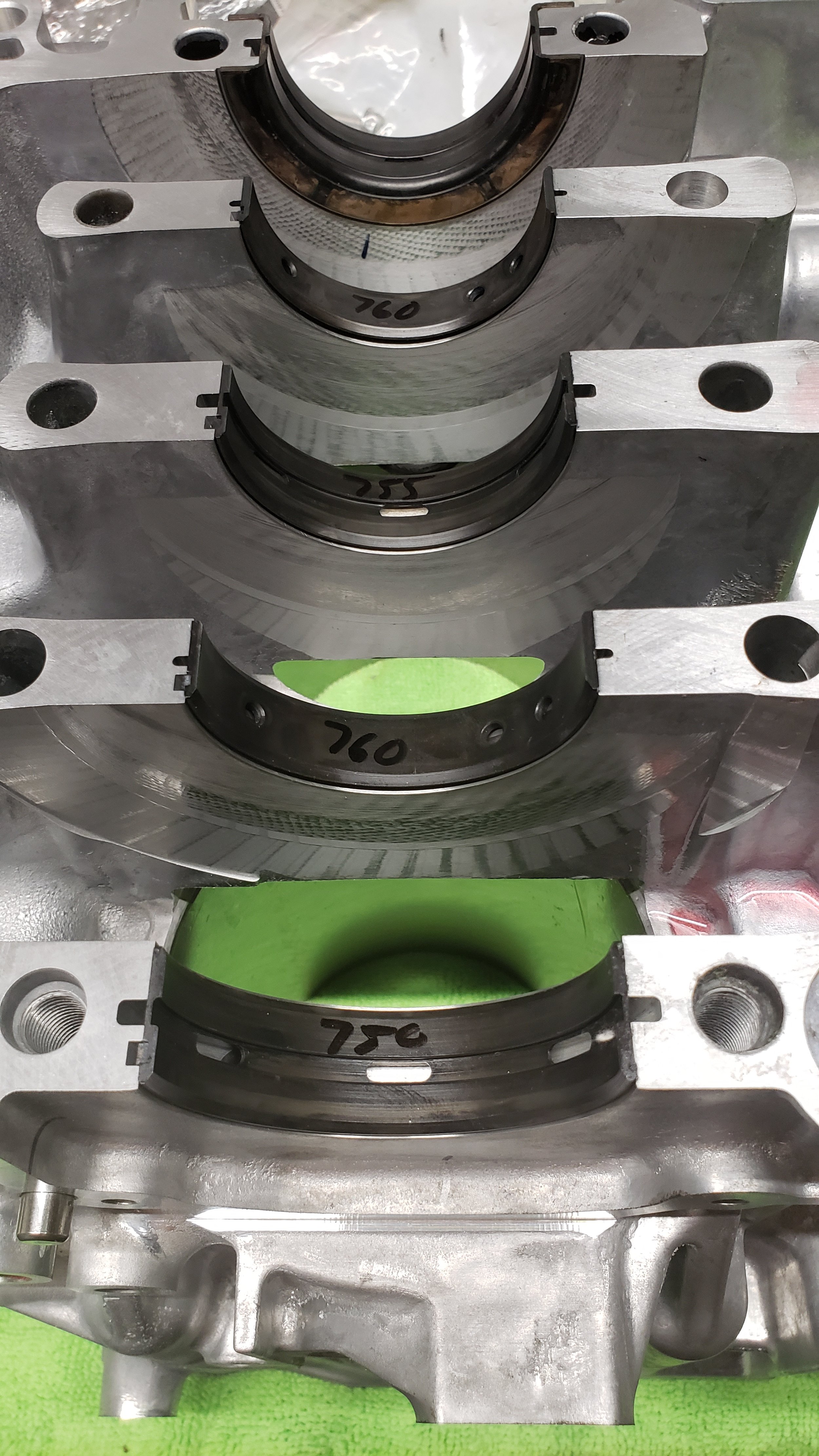

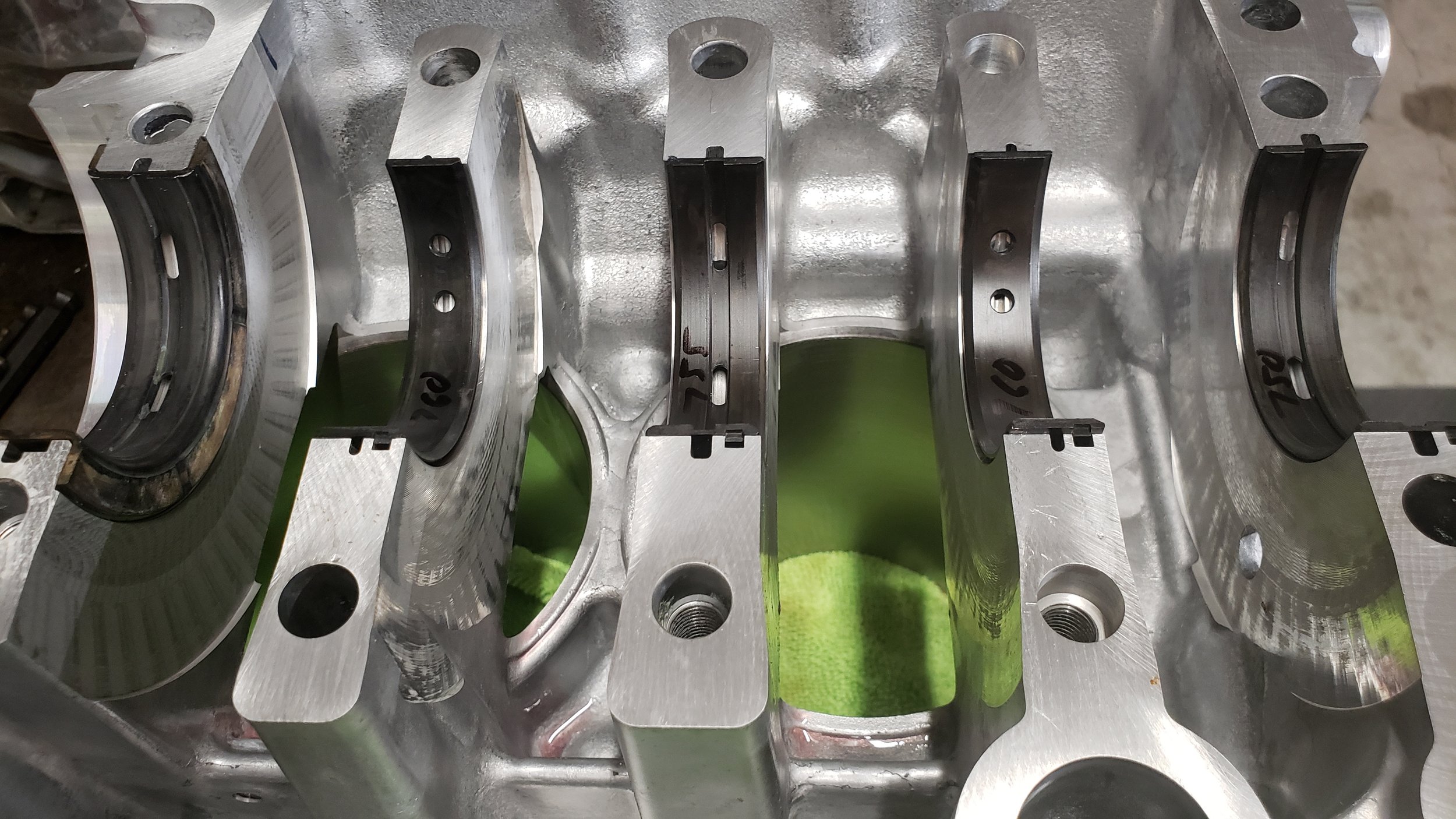

Fitted to our exact standards, competition crank and rod bearing are assembled to a crank that has been verified for perfect trueness . Our bearings and clearances have been tested for 10,000+ miles of racing. You may ask us how is this possible? It's very common for racing teams to run new engines multiple times in a racing season but we would not allow this for our long term R&D. The only way to have long term durability data on your engine program is to continue using the same parts. Each season or sometimes midway through the season we would tear down our motors to inspect how the parts were holding up and how our building specifications were performing. We would inspect items such as cylinder wear, ring wear, piston wear, oil consumption, hardware fatigue, and finally crank and rod bearing wear. As long as there was no component failure we would reuse the same bearings, crank, rods, block, and pistons and continue the durability testing.

It was not uncommon for us to push all the extremes to find the maximum and minimum operating range of each component and it's clearance. With this data we have been able to build an engine that not only makes huge power but has near OEM oil level consumption. All too often motors are built too loose causing lots of engine noise, too much cylinder blow-by, and major oil consumption issues. We have tested our combination to deliver the tightest, most trouble free, and durable engine you can buy at any price.

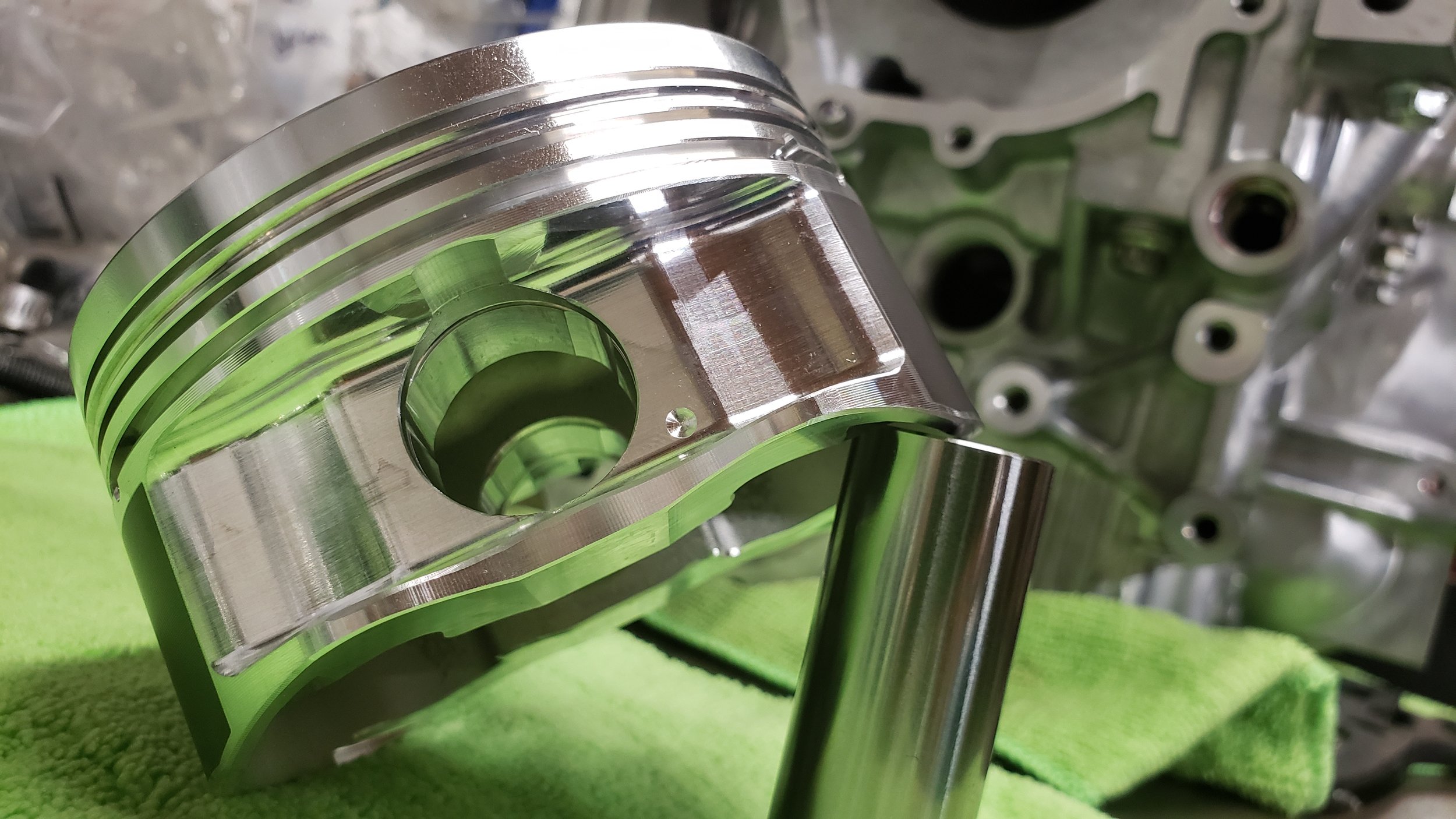

Element Tuning's engines are fitted with Manley forged pistons and rings, along with 4340 forged H beam rods which are manufactured to the highest standards in the industry. Element Tuning has fully tested these rods in our Time Attack program with exceptional success and performance. Each rod is CNC machined from 4340 steel forgings, shot peened, stress relieved, heat treated, and magnafluxed for uncompromised strength and reliability. Precision machined in the USA to within .0002" ensures exacting fitment and rod length is set to exact OEM specification at 5.137," not shorter like many other rods.

*Engines are built to order so please allow appropriate delivery time*

*Optional additions such as gasket sets and head studs are available at check out*

Element Tuning's Pro Comp short blocks were born with a racing pedigree. Our engine program has over 13 years of R&D through thousands of miles racing Subaru engines exclusively. Every specification these engines are blueprinted to were derived from our long term racing data. We build the best engines you can buy! We're confident saying this as every aspect of these motors has been tested and verified under the most demanding racing circumstances. Element Tuning Pro Comp Short Block engines are built from 100% new components and starts life from a Subaru STi bare block and a STi forged crankshaft. Blocks are then fitted with billet CNC closed deck inserts, bored to 99.75 mm, honed, and then decked.

Fitted to our exact standards, competition crank and rod bearing are assembled to a crank that has been verified for perfect trueness . Our bearings and clearances have been tested for 10,000+ miles of racing. You may ask us how is this possible? It's very common for racing teams to run new engines multiple times in a racing season but we would not allow this for our long term R&D. The only way to have long term durability data on your engine program is to continue using the same parts. Each season or sometimes midway through the season we would tear down our motors to inspect how the parts were holding up and how our building specifications were performing. We would inspect items such as cylinder wear, ring wear, piston wear, oil consumption, hardware fatigue, and finally crank and rod bearing wear. As long as there was no component failure we would reuse the same bearings, crank, rods, block, and pistons and continue the durability testing.

It was not uncommon for us to push all the extremes to find the maximum and minimum operating range of each component and it's clearance. With this data we have been able to build an engine that not only makes huge power but has near OEM oil level consumption. All too often motors are built too loose causing lots of engine noise, too much cylinder blow-by, and major oil consumption issues. We have tested our combination to deliver the tightest, most trouble free, and durable engine you can buy at any price.

Element Tuning's engines are fitted with Manley forged pistons and rings, along with 4340 forged H beam rods which are manufactured to the highest standards in the industry. Element Tuning has fully tested these rods in our Time Attack program with exceptional success and performance. Each rod is CNC machined from 4340 steel forgings, shot peened, stress relieved, heat treated, and magnafluxed for uncompromised strength and reliability. Precision machined in the USA to within .0002" ensures exacting fitment and rod length is set to exact OEM specification at 5.137," not shorter like many other rods.

*Engines are built to order so please allow appropriate delivery time*

*Optional additions such as gasket sets and head studs are available at check out*

Element Tuning's Pro Comp short blocks were born with a racing pedigree. Our engine program has over 13 years of R&D through thousands of miles racing Subaru engines exclusively. Every specification these engines are blueprinted to were derived from our long term racing data. We build the best engines you can buy! We're confident saying this as every aspect of these motors has been tested and verified under the most demanding racing circumstances. Element Tuning Pro Comp Short Block engines are built from 100% new components and starts life from a Subaru STi bare block and a STi forged crankshaft. Blocks are then fitted with billet CNC closed deck inserts, bored to 99.75 mm, honed, and then decked.

Fitted to our exact standards, competition crank and rod bearing are assembled to a crank that has been verified for perfect trueness . Our bearings and clearances have been tested for 10,000+ miles of racing. You may ask us how is this possible? It's very common for racing teams to run new engines multiple times in a racing season but we would not allow this for our long term R&D. The only way to have long term durability data on your engine program is to continue using the same parts. Each season or sometimes midway through the season we would tear down our motors to inspect how the parts were holding up and how our building specifications were performing. We would inspect items such as cylinder wear, ring wear, piston wear, oil consumption, hardware fatigue, and finally crank and rod bearing wear. As long as there was no component failure we would reuse the same bearings, crank, rods, block, and pistons and continue the durability testing.

It was not uncommon for us to push all the extremes to find the maximum and minimum operating range of each component and it's clearance. With this data we have been able to build an engine that not only makes huge power but has near OEM oil level consumption. All too often motors are built too loose causing lots of engine noise, too much cylinder blow-by, and major oil consumption issues. We have tested our combination to deliver the tightest, most trouble free, and durable engine you can buy at any price.

Element Tuning's engines are fitted with Manley forged pistons and rings, along with 4340 forged H beam rods which are manufactured to the highest standards in the industry. Element Tuning has fully tested these rods in our Time Attack program with exceptional success and performance. Each rod is CNC machined from 4340 steel forgings, shot peened, stress relieved, heat treated, and magnafluxed for uncompromised strength and reliability. Precision machined in the USA to within .0002" ensures exacting fitment and rod length is set to exact OEM specification at 5.137," not shorter like many other rods.

*Engines are built to order so please allow appropriate delivery time*

*Optional additions such as gasket sets and head studs are available at check out*